Check if the lumen is regular and the wall thickness is uniform. High-quality steel wire pipes have inner cavities and outer edges that form evenly distributed, standard circular walls. Take a large steel wire pipe with an 89mm inner diameter and 7mm wall thickness as an example. Poor-quality pipes might have a thick part of 7.5mm and a thin part of only 5.5mm. This unevenness makes them prone to bursting or deformation under high pressure, as the pipe wall bears stress unevenly.

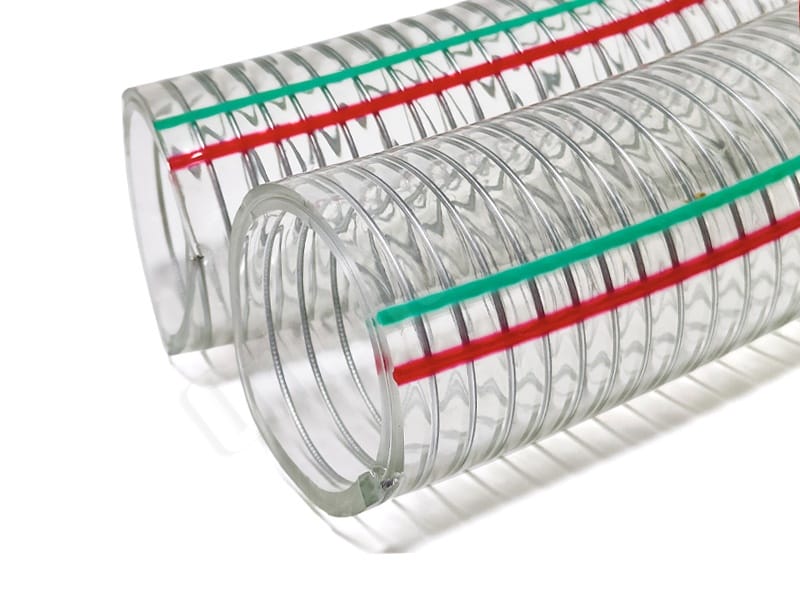

Look for bubbles or other visible impurities on the pipe wall. High-quality steel wire pipes have clear, impurity-free walls. In contrast, defective ones may turn yellow due to aging or long-term improper storage.

Smell the pipe. High-quality steel wire pipes have only a slight plastic odor, with no other petrochemical smells. Low-grade ones, however, often have a diesel-like smell—especially in summer.

Feel the pipe’s surface. High-quality steel wire pipes have smooth inner and outer walls, with a good hand feel. Inferior ones feel rough.

Measure the wall thickness correctly. Cut off both ends of a large steel wire pipe. Then select the middle section as a sample for testing. This prevents illegal manufacturers from manipulating the ends—making them thicker than the actual, thinner middle part.

Test the steel wire’s strength and toughness. Cut a few centimeters of steel wire from both ends of the PVC pipe. Fold it repeatedly. Poor-quality wire will break after one or two folds. High-quality PVC steel wire pipes use wires that can only be cut with special tools. The steel wire’s quality determines the entire pipe’s quality. PVC steel pipes with faulty wires are prone to irreversible deformation.