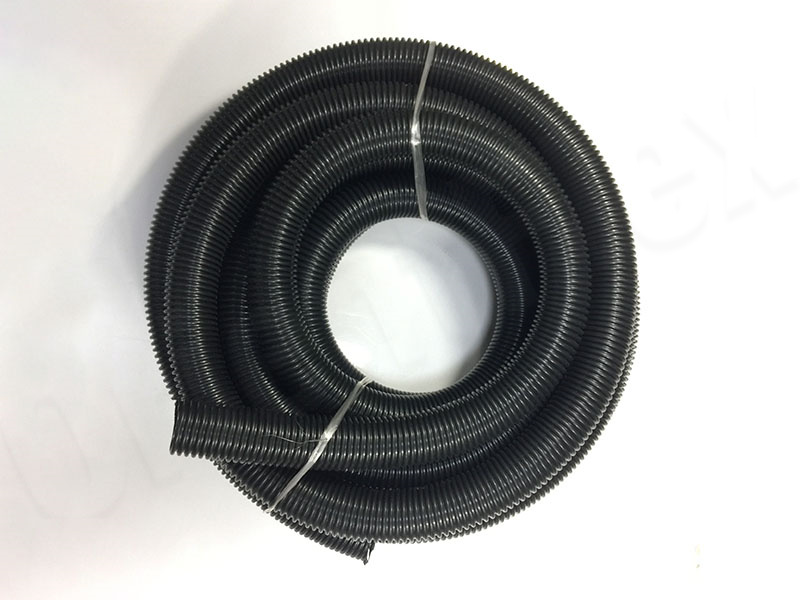

Industrial hoses encompass a broad category, including specialized subtypes like food-grade hoses, vacuum cleaner tubes, and high-temperature air ducts. Today, let’s focus on industrial vacuum hoses. While their materials are relatively common, many users overlook their unique features. Let’s dive into what makes them essential.

Key Features of Industrial Vacuum Hoses

1. Smooth Surface and Inner Wall

First, examine the hose’s appearance: both its surface and inner wall are remarkably smooth. During use, dust inevitably enters the tube, but the smooth interior prevents dust from adhering. This means users don’t have to worry about clogs. Cleaning is hassle-free—simply use a hair dryer or soak the hose in warm water.

2. Exceptional Flexibility

Second, these hoses offer superior flexibility. Bending is inevitable during operation, but low-quality materials can crack that won’t recover. Industrial vacuum hoses, however, can bend more than five times farther than ordinary materials. This means no chipping or permanent marks, even with frequent use.

3. Strong Anti-Aging and Antioxidant Properties

Third, they resist aging and oxidation effectively. Industrial environments expose hoses to harsh air or liquids, so long-term durability is critical. These hoses are designed to withstand such conditions, ensuring reliable performance over time without degradation.

4. Cost-Effective Pricing

Fourth, industrial vacuum hoses are budget-friendly. The production materials don’t incur high costs, and most suppliers use mass production to further reduce expenses. This translates to lower purchase prices for users. That said, prices can vary based on brand, quality, and specifications. It’s crucial to choose a reputable supplier and understand market rates to get the best value.